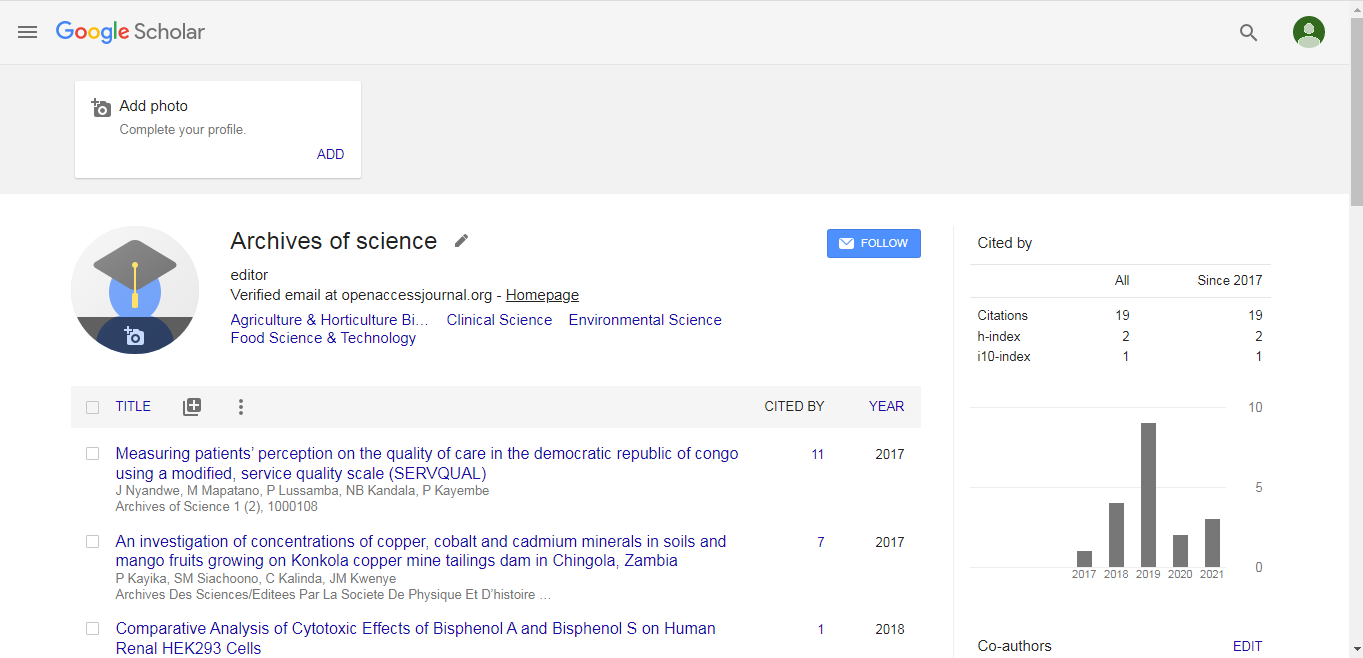

Biomaterials 2019: Used of 3D printing technology in orthopedic oncology: Custom surgical guide and patient-matched prosthesis - Sutipat Pairojboriboon - Phramongkutklao Hospital and College of Medicine

*Corresponding Author:

Copyright: © 2020 . This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Statement of the Problem: Presenting the clinical outcome of patient-matched prosthesis and custom surgical guide via 3D printing technology.

Methodology & Theoretical Orientation: Total 11 cases of benign and malignant tumors applying 3D printing assisted surgery which are 6 anatomical models, 11 custom surgical guides, and 4 patient-matched prostheses. Image acquisition was derived from CT scan, 0.5-3 mm slices cut. The contralateral CT scan was used as a prototype for creating the patient-matched prosthesis while the ipsilateral CT scan was used in anatomical model and surgical cutting guide. Anatomical models, used as the preoperative planning tools, were printed by a fused deposition modeling (FDM) printer with acrylonitrile butadiene styrene (ABS) material and a Binder Jetting machine, 3D Systems Z Printer 650 using VisiJet PXL materials. 11 custom surgical guides were printed by Envision TEC??? E-Guide Tint and E-Model. 4 of patientmatched prostheses, which are 2 fingers prostheses, 1 of total constrained proximal interphalangeal (PIP) joint prosthesis, and 1 of navicular 3D custom scaffold, were printed by selective laser-melted (SLM) printer with Ti6Al4V. The pore geometry selective laser-melted Ti6Al4V bone scaffolds was 200 µm, strut size and 500 µm, pore size. Time to produce was 3-20 days. Preoperative planning via anatomical model showed better outcomes in term of decrease operative time and blood loss. Custom surgical guide demonstrated better outcomes comparing to navigation surgery in term of achieving same accuracy but less resection time. According to bone tumors can be found in the unusual locations which there is no off the shelf prosthesis, patient-matched prosthesis has gained popularity and played a major role in this area.

Background: Bone tumors are generally rare diseases. They can occur in various locations of the skeletal system which sometimes are difficult to access such as the peri-acetabular area and the posterior part of the distal femur and proximal tibia and near the neurovascular bundles. Moreover, some conditions such as bone metastasis from the thyroid or renal cancer can cause high volume bleeding conditions. A thorough preoperative plan to reduce operative time is critical. Currently, 3D (3 dimensional) printing technology has gained popularity in medicine especially in orthopedic oncology because of the ability to create patient-specific, accurate, and high fidelity

models that can be used to create patient-specific operational plans and prostheses. Much literature supports using 3D printing in clinical practice with most revolving around using the 3D model as a physical simulation to aid in pre-operative planning and the fabrication process of customized 3D printed implants. Examples of clinical use in the 3D model are reshaping plates for minimally invasive fixation in calcaneal fracture, pre-operative planning for minimally invasive fixation in comminuted fracture of tibial plateau and a combination of 3D printing and computer-assisted virtual surgery regarding the acetabular fracture. In addition, some bone tumor cases have a soft tissue extension from the cortex; thus, mandating the use of more advanced reconstruction techniques combining computed tomography (CT) and magnetic resonance imaging (MRI) creating the subject-specific 3D model were performed. Segmentations which use such fused imaging offers more accurate information than either CT or MRI alone by combining the different tissue sensitivities of each modality.

While CT images are excellent for segmenting bony structures, MRI images play a major role to segment non-bony structures. Customized 3D printed implants are increasingly popular and are being currently manufactured for a variety of anatomic sites. These personalized advantages of patient-matched and unique skeletal structures are featured in studies including 3D printed metacarpal prosthesis, customized 3D printed knee prosthesis and customized complicated acetabular prosthesis. Essential to the successful integration of this technology is the inter-professional cooperation and communication between the orthopedic surgeon and the engineer as they have technological and educational differences.

For example, the engineer may not be familiar with anatomy, epidemiology, surgical approach and resection/reconstruction procedures. In contrast, the orthopedic surgeon may not know the numerous steps of the fabrication process of a 3D-printed physical model that can be described as a combination of 3D volumetric imaging acquisition, image postprocessing, and 3D printing technology. Postprocessing of Digital Imaging and Communications in Medicine (DICOM) imaging data is an important step to generate the Standard Tessellation Language (STL) file that is able to be read by 3D printers. Computeraided design (CAD) software is for refining or instrument/device designing, model quality checking, and file fixing. 3D printers use data encoded in STL file format to successively fuse thin layers of material to create a 3D object.

Conclusion & Significance: Applying fabrication of 3D printing technology, via custom surgical guide and patientmatch prosthesis in bone tumors surgery, has proved the advantages in limb sparing surgery