Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ºÚÁÏÍø Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

ºÚÁÏÍø Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

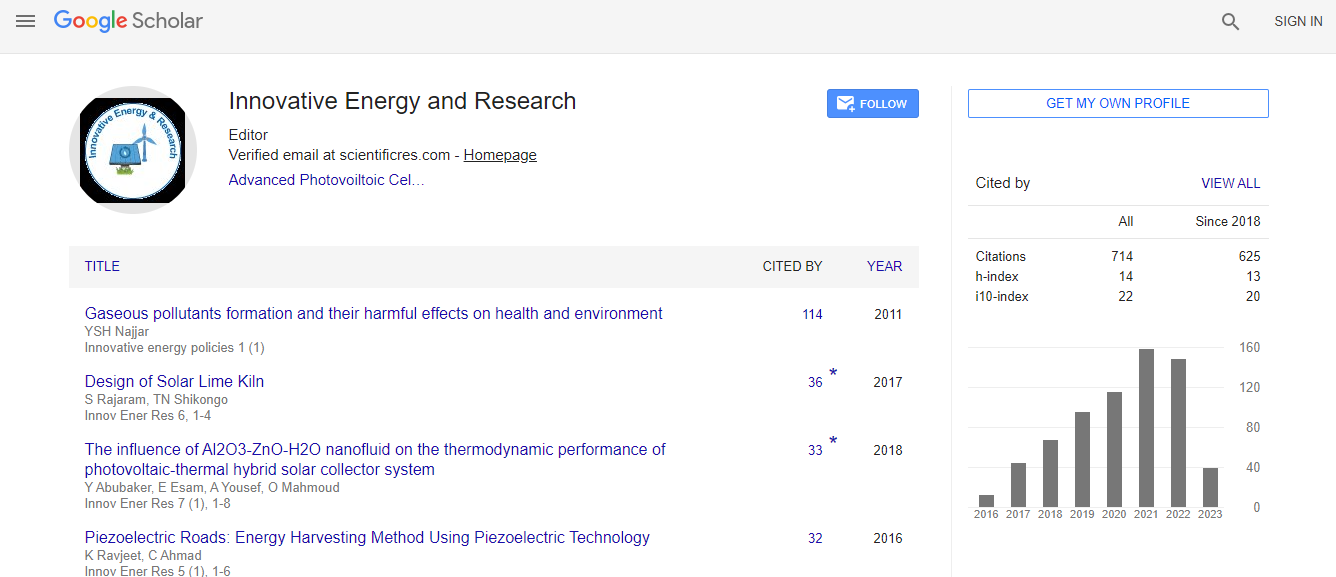

Citations : 712

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

A sustainable technology for extraction of cobalt and nickel from laterite ores

20th International Conference on Advanced Energy Materials and Research

Guangqing Zhang, Oleg Ostrovski, Jun Yang, Yong Li Cui and Sharif Jahanshahi

University of Wollongong, AustraliaUniversity of NSW, AustraliaMeta-Logical Solutions Pty Ltd., Australia

ScientificTracks Abstracts: Innov Ener Res

DOI:

Abstract

Cobalt and nickel are two of the key base metals for the production of high energy density batteries. Their availability and costs are key factors that will determine the success in popularizing electric vehicles in the future. This paper presents a potential technology for sustainable extraction of cobalt and nickel from laterite ores. The major phases in a garnierite laterite ore include chlorite, talc, hematite, and quartz. In the technology, cobalt and nickel oxides are selectively reduced in a controlled atmosphere to their metal states while the reduction of iron oxides is minimized. At 740°C in 60 vol.% CO-40 vol.% CO2, 91% Ni and 94% Co in the particles <53 μm and 85% Ni, 99% Co in the particles 53-200 μm but less than 20% Fe are reduced to metals. The reduced metals are then carbonylated by carbon monoxide in a pressurized reactor at ~100°C. Using sulfur as a catalyst and under CO pressure of 15 atm., 97% of nickel from reduction of NiO is carbonylated. The conditions for the carbonylation of nickel from reduced laterite ore needs to be optimized. The reduced nickel and iron are separated from the ore due to formation of volatile carbonyls, and are recovered from the carbon monoxide stream. Cobalt carbonyl left with the reduced ore is further separated by vaporization or dissolution and recovered as metal product. The proposed technology has the advantages of low energy costs and low production costs, and so will be suitable for the extraction of cobalt and nickel from the low-grade laterite ores which will expand the cobalt and nickel resources, and so contributes to the sustainable development of the related metals and their applications. Recent Publications: 1. Olivetti E A, Ceder G, Gaustad G G and Fu X (2017) Lithium-ion battery supply chain considerations: analysis of potential bottlenecks in critical metals. Joule 1(2):229-243 2. Yang J, Zhang G, Ostrovski O and Jahanshahi S (2013) Changes in an Australian laterite ore in the process of heat treatment. Minerals Engineering 54:110-115. 3. Yang J, Zhang G, Jahanshahi S and Ostrovski O (2015) Reduction of a garnieritic laterite ore by CO-CO2 gas mixtures. INFACON XIV 518-527.Biography

Guangqing Zhang has expertise in the development of sustainable technologies for metals production. He has applied the kinetics and thermodynamics and engineering knowledge in the development of alternative technologies and improvement of current technologies for metals production. His research fields include process metallurgy, energy conversion, and recycling of waste materials.

E-mail: gzhang@uow.edu.au