Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

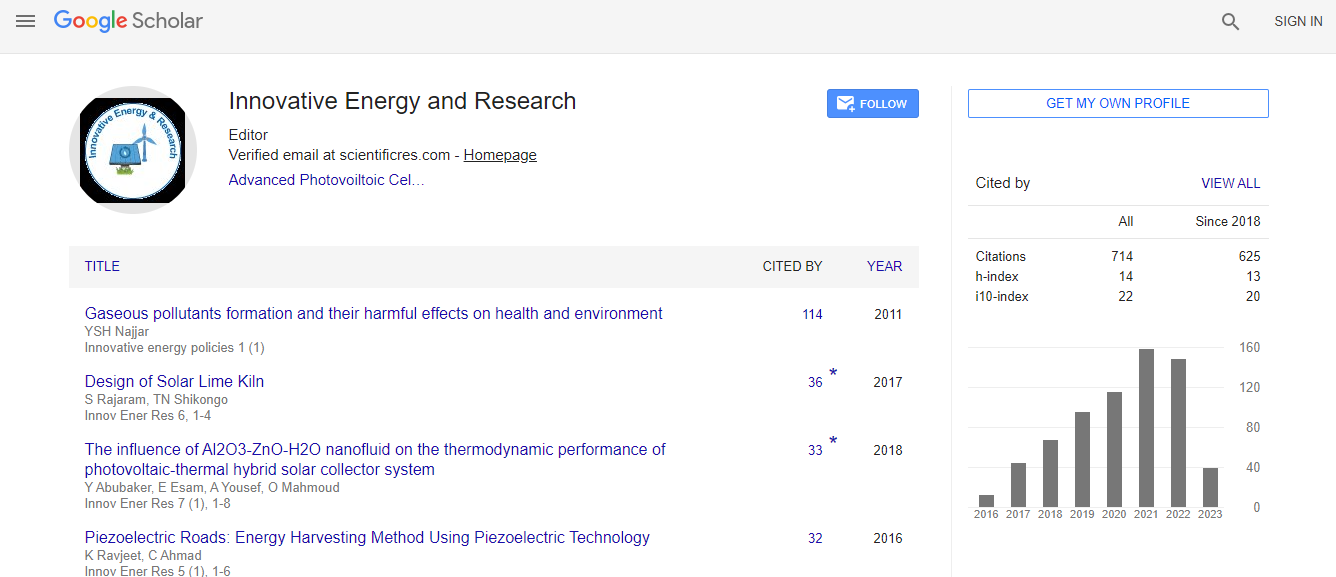

Citations : 712

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

New approach for local treatment of defects on glazed ceramics by CO2 laser

20th International Conference on Advanced Energy Materials and Research

N M Ferreira, J M Fernandes, C M S Freitas, F Rey Garcia, J Carneiro, M N Capela, R Santos, A J S Fernandes, M P Seabra and F M Costa

University of Aveiro, PortugalCICECO - Aveiro Institute of Materials, PortugalCoimbra iParque - Parque tecnológico de Coimbra, Portugal

Posters & Accepted Abstracts: Innov Ener Res

DOI:

Abstract

The evolution on ceramic industry is constant and significant improvements in automation and process efficiency are necessary. The treatment of small defects usually involves a new firing to repair small defects with only a few mm2, representing a significant increase in costs productions. One option is the use of laser technology to in situ repair defects of the ceramic pieces, preventing all the extra costs associated with a re-firing. Several authors indicating that CO2 laser is strongly absorbed by the ceramic material, allowing the repairs in a rapid and highly localized manner. This study present a new approach of using a CO2 laser to repair small defects on the surface of ceramics glazed. The application of laser technology to the traditional repairing material proved problematic since it was detected the formation of microcracks ascribed to thermal stresses generated by the high temperature gradients. To overcome this, alternative approaches through changing the interaction area of the laser beam on the piece to repair, in order to reduce the thermal stresses due to the heat by laser beam. Repaired defects were evaluated based on the velocity of the piece motion to laser focus, power of the laser, presence of cracks on the surface and the size of microscopic cracks. The incident laser power, duration of laser heating/cooling and velocity of approach were analysed. After laser treatment the restored surfaces and cross sections were analysed by μ-Raman spectroscopy, 3D optical profilometry and optical microscopy together with optical and chemical/mechanical characterization. The results show the effect of velocity and power laser of the spread of cracks and microcracks on the surface of material irradiated. Nevertheless, this new approaches show good results to implement laser technology in the repair of ceramic industry. Recent Publications: 1. K. Osvay, I. Képíró, and O. Berkesi, “Laser treatment of white China surface,” Appl. Surf. Sci., 2006. 2. S. Rodríguez-López, R. Comesaña, J. del Val, A. Durán, V. M. Justo, F. C. Serbena, and M. J. Pascual, “Laser cladding of glass-ceramic sealants for SOFC,” J. Eur. Ceram. Soc., vol. 35, no. 16, pp. 4475–4484, Dec. 2015. 3. N. B. Dahotre and S. P. Harimkar, Laser Fabrication and Machining of Materials. Springer, 2008. 4. J. D. Majumdar and I. Manna, Laser-Assisted Fabrication of Materials. 2012. 5. X. Li, J. Wang, L. L. Shaw, and T. B. Cameron, “Laser densification of extruded dental porcelain bodies in multimaterial laser densification process,” Rapid Prototyp. J., vol. 11, no. 1, pp. 52–58, 2005. 6. N. Basile, M. Gonon, F. Petit, and F. Cambier, “Processing of a glass ceramic surface by selective focused beam laser treatment,” Ceram. Int., 2016. 7. D. Triantafyllidis, L. Li, and F. H. Stott, “Crack-free densification of ceramics by laser surface treatment,” Surf. Coatings Technol., 2006.Biography

Nuno Ferreira, is a PhD in Physics Engineering (2014), currently is a post-doc researcher at i3N, Physics Department and CICECO, Department of Materials and Ceramic Engineering at University of Aveiro, Portugal. He participated as a collaborator and research fellow in several R&D projects on material science. He is an experienced researcher in study and development of ceramics-based materials, prepared through conventional methods (melting, solid stated), with particular focus on laser processing (crystal growth – LFZ and surface sintering). Present sample characterization skills include various techniques such as, electrical conductivity and magnetic properties of various oxide materials. Current focus materials: thermoelectrics, ferroelectrics and glass matrices doped with transition metals and rare earth for energy storage and conversion applications. Main expertise is related to structural, magnetic and electrical properties of materials prepared by laser processing.

E-mail: nmferreira@ua.pt