Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

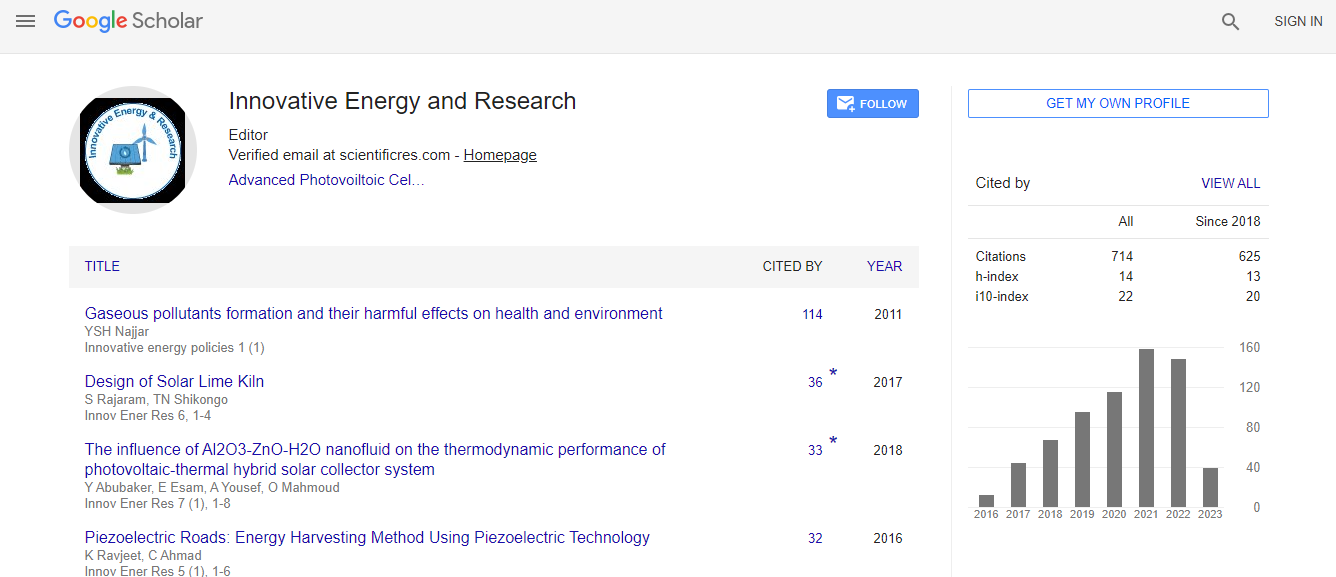

Citations : 712

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Selection and stability investigations of polymers for latent heat storages

Joint Event on 2nd International Conference on Renewable Energy and Resources & Energy Materials and Fuel Cell Research

Helena Weingrill, K Resch-Fauster, T Lucyshyn and C Zauner

Montanuniversitaet Leoben, AustriaAustrian Institute of Technology, Austria

ScientificTracks Abstracts: Innov Ener Res

DOI:

Abstract

Semi-crystalline polymers offer many advantageous properties which are required for phase change materials (PCM) in latent heat storages. They exhibit high heats of fusion and a wide range of melting temperatures. Additionally, specific characteristics (e.g. thermal conductivity) can be easily tailored via compounding. However, only high-density polyethylene (HDPE) has been considered as suitable PCM so far. A Differential Scanning Calorimeter (DSC) was first used to identify candidate polymer classes according to their storage capacity and application temperature. The most promising polymer types were found to be: polyethylene (PE), polypropylene (PP), polyamides (PA), polyoxymethylene (POM) and polyethylene glycol (PEG). An HDPE, a PA 6, a PA 4.6 and a POM copolymer were further selected for application-oriented stability investigations. Cyclic and static thermal loads were applied to examine their thermal and thermo-oxidative stability. Thermal cycling was done in a DSC up to 3000 cycles in air and nitrogen atmosphere and thermo-physical characteristics were recorded simultaneously. Whereas the PA 4.6 degraded steadily, the thermo-physical characteristics of HDPE and the PA 6 were not affected. The stability of POM could be improved by utilizing a closed system. Static thermal outsourcing was done above melting temperature in circulating air ovens. Fourier Transform Infrared Spectroscopy (FTIR) revealed that degradation occurred mainly on the surface leaving the storage-relevant characteristics of the bulk unaffected. These results outline the applicability of polymers as PCM. This research project is funded by Klima- und Energiefonds (Austrian Climate and Energy Funds) and carried out within the framework of the program “Energieforschung”. The Austrian Research Promotion Agency (FFG) is gratefully acknowledged for funding this work under Grant No. 848914 (StoreITup-IF).Biography

Helena Weingrill is a PhD student at the Chair of Materials Science and Testing of Polymers at Montanuniversitaet Leoben in Austria. She finished the bachelor’s and master’s programme of Polymer Science and Engineering also at the Montanuniveritaet Leoben.

E-mail: helena.weingrill@unileoben.ac.at