Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ 黑料网 Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

黑料网 Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

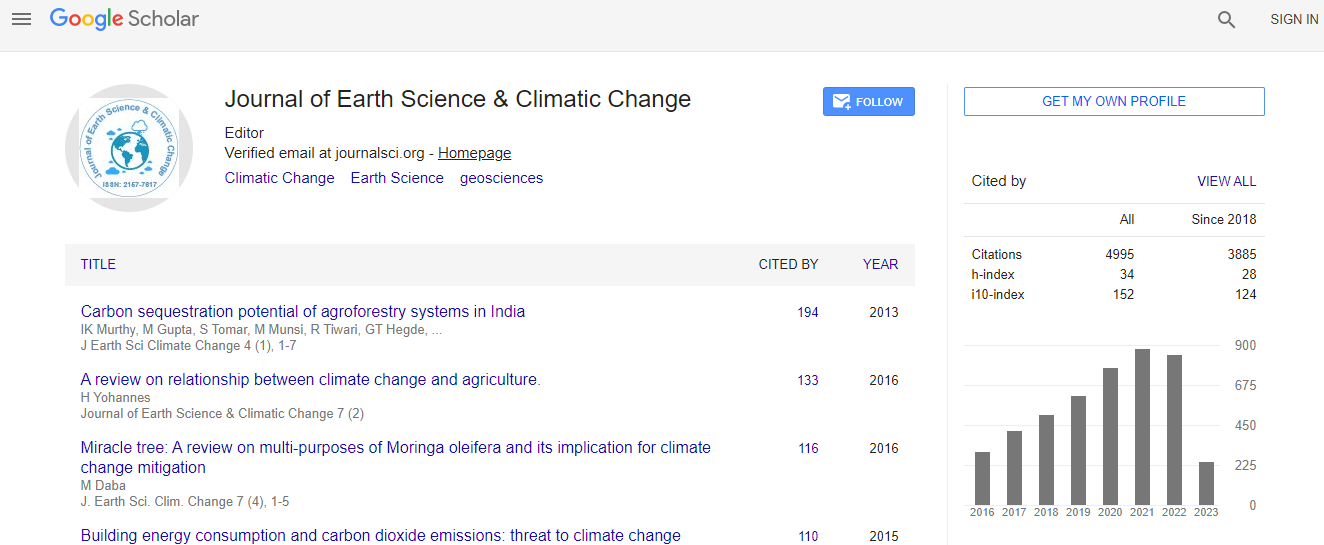

Citations : 5125

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- Ulrich's Periodicals Directory

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Proquest Summons

- SWB online catalog

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

In Association with

Feasibility study of in situ precipitated calcium carbonates (PCC) synthesis technology for paper recycling by the capture and direct utilization of low concentration CO2

3rd World Congress on Climate Change and Global Warming

Ji Whan Ahn

Korea Institute of Geosciences and Mineral Resources, South Korea

Keynote: J Earth Sci Clim Change

DOI:

Abstract

Feasibility study of in situ PCC synthesis technology for paper recycling in the Phong Khe Paper Craft Village of Vietnam has a green manufacture model and solution for environmental remediation. In situ PCC synthesis technology is a recycling technique of waste paper and capture and direct utilization of low concentration of CO2 with PCC filler which improves whiteness and machinery lifetime of paper. This paper recycling with in situ PCC synthesis has been developed and popularized in other countries. It is featured by a process of mixing waste pulp with PCC formed by quick lime (CaO) and CO2 in an in situ PCC Reactor. In general, PCC synthesis processes are divided into the two following steps in paper recycling process: (1) CaO is turned into slaked lime (calcium hydroxide, Ca(OH)2) through its reaction with water, which is called hydraulic process and (2) PCC is synthesized by the reaction between Ca(OH)2 and carbonate ions (CO32-). The technology has several advantages. It reduces overall manufacture costs and needs fewer corrosive chemicals, thus extending machinery lifetime. Most of all, the process is more environmentally friendly due to following reasons: Easier recycling CO2 generated from paper industry, wood consumption reduction, less wastewater and byproduct production from the process and less energy consumption owing to shorter refining and drying times. It is calculated that recycling one ton of waste paper can reduce 937 kg CO2, 3.22 KWh energy, 42,465 L water and 340 kg waste. In order to apply the paper recycling technology, an action plan which collects waste papers is required as a climate change adaptation. To spread the collection of waste papers, the system which transfers the collected waste papers to cashable mileage needs to be introduced in Phong Khe village and extend to entire of Vietnam. The system needs to be started with students and citizens as an education to sustainable paper recycling.Biography

Ji Whan Ahn has completed her BS, MS and PhD degree in Mining and Minerals Engineering from Inha University and she has completed Master’s degree in Resources Environmental Economics from Yonsei University. Currently she is working as an Executive Director in Carbon Resource Recycling Appropriate Technology Center, Korea Institute of Geosciences and Mineral Resources, President for Korea Institute of Limestone & Advanced Materials, Chairperson and Vice President of Korea Institute of Resources and Recycling. She has published more than 175 papers, 716 proceedings papers/conference presentations and 71 patents. She has received many awards for her research excellence.