Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

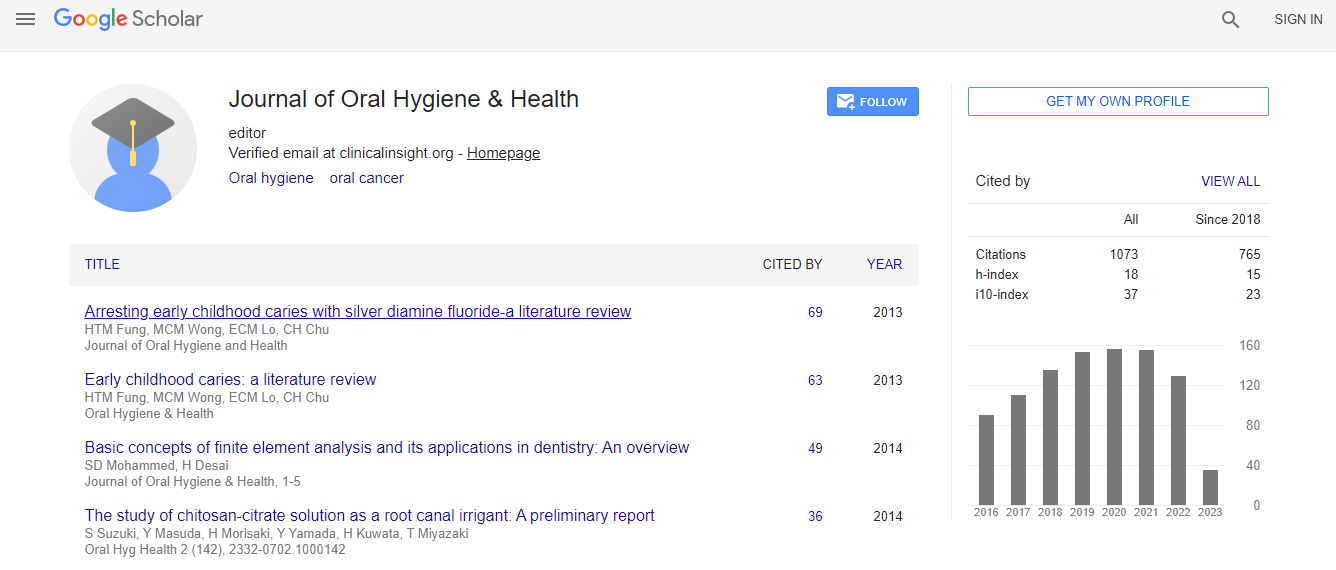

Citations : 1073

Indexed In

- Index Copernicus

- Google Scholar

- Open J Gate

- JournalTOCs

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

The effect of different finish lines on marginal and internal fit of a ceramic crown fabricated by CAD/CAM system

2nd International Conference on Restorative Dentistry and Prosthodontics

Alaa Elaraby

Alexandria University, Egypt

Posters & Accepted Abstracts: J Oral Hyg Health

DOI:

Abstract

This study evaluates the marginal discrepancy of CAD/CAM ceramic coping of two different finish line preparations. Two master steel dies were prepared, one with rounded shoulder (RS), and the other with chamfer (C). CEREC 3D Sirona CAD/CAM system and Software Version 2.80 R2400 were used in this study. The optical camera was fixed in a distance of 10 cm and 90 degree to take the same optical capture for each sample. CEREC cylinder pointed bur was used to cut the Ivoclar Vivadent ProCAD Milling Blocks to fit on the dies. Twenty copings were prepared, ten CAD/CAM ceramic coping from each finish line preparation. Each coping with its corresponding die was sectioned longitudinally using ISOMET 2000 PRECISION SAW. The marginal discrepancy was then evaluated in Travelling Microscope. The data of marginal discrepancy in micrometer (�?¼) were subjected to two way analysis of variance using SPSS version 15. The mean value of marginal discrepancy was 135.48 �?¼m and 85.7 �?¼m for chamfer group (C) and rounded shoulder group (R) respectively. Furthermore, there was a significant difference in the axial fitting on the occlusal side (occlusal adaptation) of the crowns between the chamfer and shoulder groups (p<0.05). Shoulder group showed the lowest mean value of 95.84 �?¼ �?± 15.02, while chamfer recorded the highest value of 137 �?¼ �?±13.09. The results showed that there was a significant difference between the two groups. It was concluded that marginal fit of CAD/CAM all-ceramic crowns with rounded shoulder finish line had better adaptation than chamfer finish line. The adaptation of CAD/CAM crowns obtained with chamfer finish line was not clinically accepted.Biography

Email: alaaraby2@gmail.com