Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ 黑料网 Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

黑料网 Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

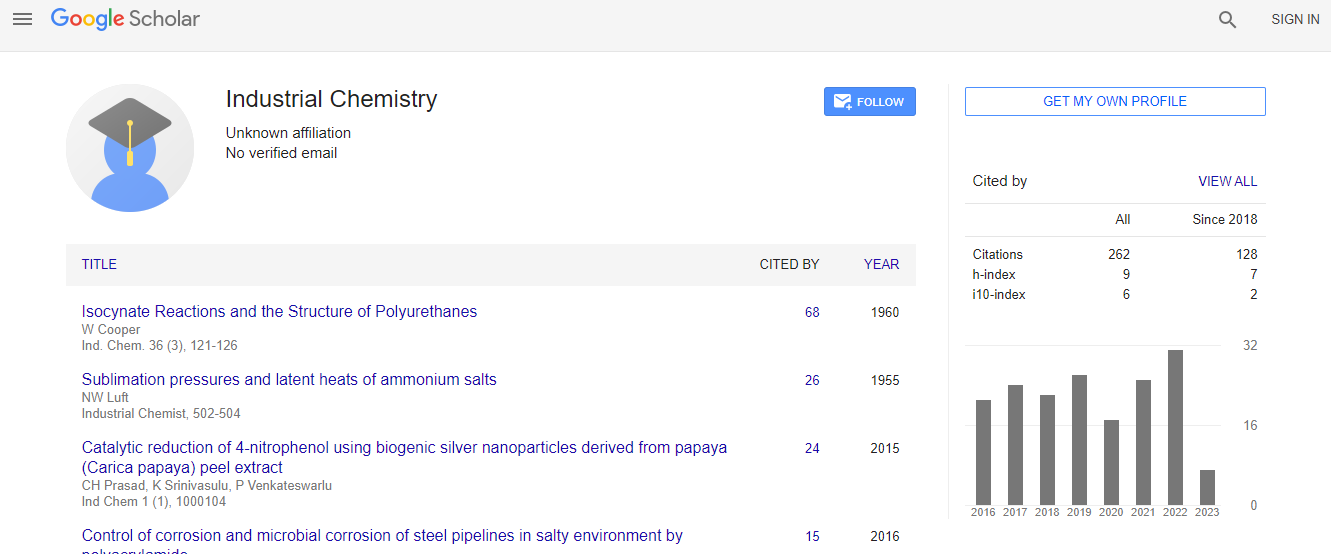

Citations : 262

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

A green polyester and products from carbon dioxide, water and solar power

2nd World Conference on Industrial Chemistry and Water Treatment

Jian Yu

University of Hawaii at Manoa, USA

ScientificTracks Abstracts: Ind Chem

DOI:

Abstract

Statement of the Problem: Carbon dioxide (CO2) is a prime green-house gas emission from industrial processes. It can be converted into bio-oil and bio-diesel through conventional photosynthesis of microalgae. The CO2 fixation rate, however, is quite low and affected by the intermittent solar irradiation. Methodology & Theoretical Orientation: An artificial photosynthetic bioprocess is developed to produce green polyester from CO2, water and solar power. In this green process, solar energy is captured using photovoltaic modules and converted into hydrogen as a stable energy source via water electrolysis. The solar hydrogen and oxygen is used to fix CO2 by a hydrogenoxidizing bacterium. Findings: Under the autotrophic growth conditions, CO2 was reduced to biomass at 0.8 g L-1 hr-1, about 10 times faster than that of the typical bio-oil-producing microalgae (Neochloris Oleoabundans) under indoor conditions. A large portion of the reduced carbon is stored in polyhydroxybutyrate (PHB), accounting for 50-60% of dry cell mass. PHB is a biodegradable thermoplastic that can find various environmentally friendly applications. The green polyester can also be converted into small chemicals (C3-C4) with different functional groups. Specifically, PHB is degraded and deoxygenated on a solid phosphoric acid catalyst, generating a hydrocarbon oil (C6-C18) from which a gasoline-grade fuel (77 wt% oil) and a biodiesel-grade fuel (23 wt% oil) are obtained via distillation. Aromatics and alkenes are the major compounds, depending on the reaction conditions. Their reaction mechanisms from crotonic acid, a major PHB degradation intermediate, are revealed and presented. Conclusion & Significance: Biodegradable plastics and high-grade liquid fuels can be directly produced from carbon dioxide, water and solar power. The productivity of the green polyester (5.3 g L-1 d-1) is much higher than that of microalgal oil (0.13 g L-1 d-1). Other technical merits of the new green process may include continuous operation under intermittent solar irradiation and convenient scale up in outdoor.Biography

Jian Yu has obtained his PhD degree from University of British Columbia in 1991, MSc from Zhejiang University in 1985 and Bachelor of Engineering (BEng) from Zhejiang Institute of Technology in 1982. He was an Assistant Professor at Hong Kong University of Science and Technology (1994-2001) and is currently a Research Professor at University of Hawaii at Manoa (2001-present). His research interest is in the area of bioprocess and bioreactor engineering and production of green plastics, chemicals and fuels from renewable resources. He has published more than 70 research papers in peer-reviewed journal as the first and/ or corresponding author, in addition to numerous book chapters and conference papers and presentations. He has three patents that have been licensed to companies and one technology has been successfully scaled up to pilot plant and commercial production.

Email: jianyu@hawaii.edu