Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

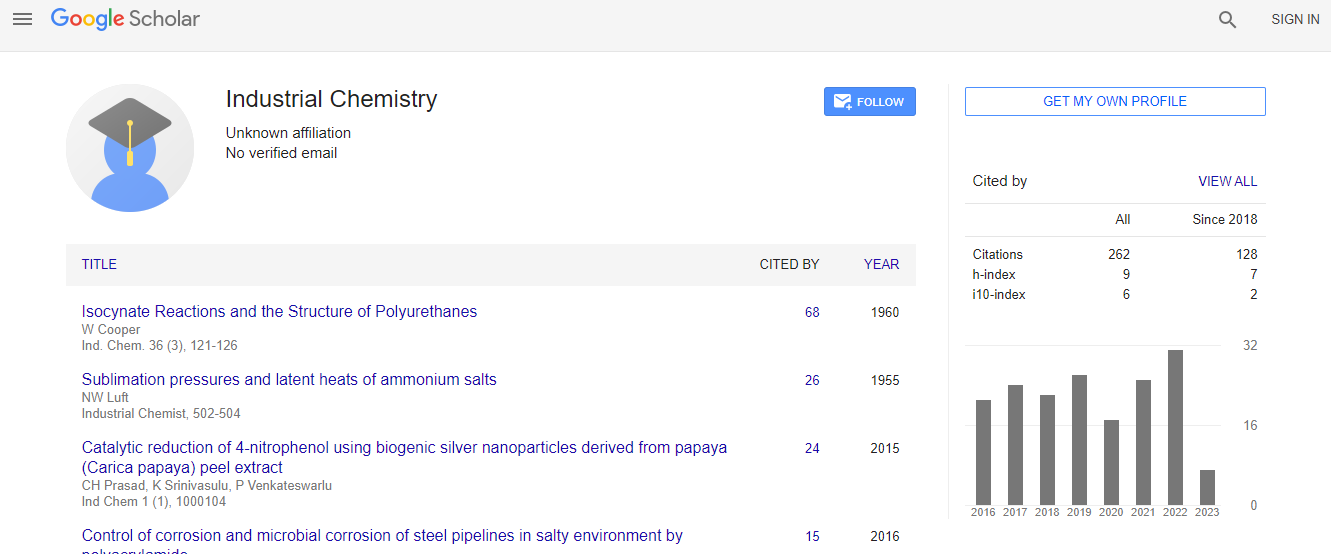

Citations : 262

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Effect of adding porcelain on properties of porous ceramic based on electromelted corundum

17th International Conference on Industrial Chemistry and Water Treatment

Zaw Ye Maw Oo

D Mendeleev University of Chemical Technology of Russia, Russia

ScientificTracks Abstracts: Ind Chem

DOI:

Abstract

Porous ceramics is used throughout the world for filtering, heat insulation, and heat protection. During filtering, important parameters are a porous structure and properties connected with it, i.e., pore size, pore size distribution, average capillary diameter, permeability, and specific surface. There is increasing interest in porous ceramic materials due their capacity to operate at high temperature in corrosive abrasive media. These materials may be used for filtering various liquid (liquid solutions in various solvents, with almost any medium pH, and melts, including metals, polymers, and salts) and also gases. In an article, the effect is studied of the radio of various fractions of electromelted corundum with a constant content of porcelain binder of mix polyvinyl alcohol (PVL) (5%) liquid on porous ceramic properties. Specimens were compacted under a pressure of 25, 50 and 100MPa and then fired at 1350�?°C and 1450�?°C. After that, the samples were prepared by impregnating the ceramic slurry polyurethane foam (PUF), followed by drying and calcining at 1450�?°C. The flexural strength of the sintered samples without PUF with burnable additives showed from 19 to 151MPa, an open porosity of 17 to 25%, and for the samples duplicated PUF after firing showed the porosity was 60-65%, the compressive strength of 3.5MPa.Biography

Zaw Ye Maw Oo has completed his PhD from D Mendeleev University of Chemical Technology of Russia by government scholarship. Now, he is attending Post-doctoral studies in that university. He has published more than five papers in reputed journals.

Email:zawyemawoo@gmail.com