Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

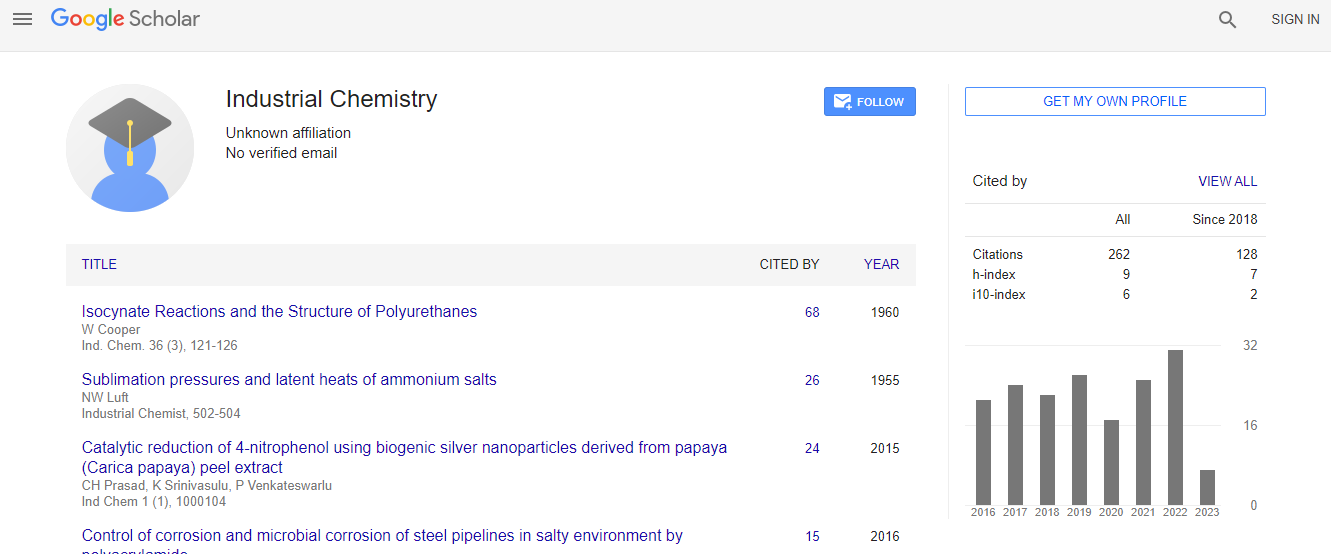

Citations : 262

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Energetic and exergetic analysis of a steam turbine power plant in an existing phosphoric acid factory

International Conference on Industrial Chemistry

Khir Tahar

National Engineering School of Gabes, Tunisia

Posters & Accepted Abstracts: Ind Chem

DOI:

Abstract

Energetic and exergetic analysis is performed on a Steam Turbine Power Plant used in a Phosphoric Acid Factory. The power plant is mainly constituted by two steam turbine cycles STGI, STGII and a turbo-blower group Tb-Bl. Mass, energy and exergy balances are established on the main compounds of the plant. A numerical code is established using EES software to perform the calculations required for the analysis considering real variation ranges of the operating parameters such as pressure, temperature and mass flow rate. The effects of theses parameters on the system performances are investigated. The minimum irreversibility rates are obtained for the condensers (0.5 MW), the deaerators (0.4 MW) and the blower (1.5 MW) followed by the pumps and steam turbines. The heat exchangers present an irreversibility rate of about 5 MW. The maximum energy efficiency is obtained for the blower followed by the heat exchangers, the deaerator and STGII. The exergy efficiency obtained for the heat exchanger, the steam turbine generator, the deaerator and the blower are 88 %, 74 %, 72 % and 66 % respectively. The exergy effeciency of STGI is analyzed taking into account the condensate flow rate. For mass flow rates through the condenser of 12, 18 and 20 t/h. The optimum HP steam flow rates feeding the turbine, leading to the maximum exergetic effeciency are 49, 51 and 56 t/h respectively. For the back pressure steam turbine STGII a maximum exergetic efficiency of about 75.5 % is obtained with HP mï�?¦ of 73 t/h.Biography

Khir Tahar is Professor in Mechanical Engineering at National Engineering School of Gabes – Tunisia. He was Adviser of the Minister of Higher Education and Scientific Research from 2012 to 2014. He received his BSc in Mechanical Engineering from the University of Tunis (1983). He obtained his MSc Degree in Energetic from the University of Paris XII (1984). He was awarded his PhD from the same University in Energetic Systems and Energy Management (1987). He obtained his Habilitation Degree in Energy System from the University of Gabes (2011). His research works cover Industrial refrigeration, Thermo-economic optimization, Power Plants and Renewable Energies.

Email: taherkhir@yahoo.fr